Making of bricks

Introduction To Clay Bricks

The burnt clay bricks are made by pressing into moulds, then these bricks are dried in kilns and removed.

Some bricks are made of metal-containing clay, baked at extremely high temperatures making them a ceramic material that is extremely strong and heat resistant.

When these bricks are used in walls, they require plastering or rendering and used in general work, with no special attractive appearance.

Though the overall method remains the same, there are certain regional variations considering the local soil and climatic conditions. In different areas, different soil types are used with respect to local situation. The general approach for firing bricks include using a massive fire, a massive volume and insulation. At our Kiln we fire large volume of bricks together with pure vessel coal imported from America which makes the best quality of bricks in all the manners and the volume itself acts as an insulator to prevent escape of heat.

History Of Bricks

A brick is a block made of clay burnt in a kiln. It is one of the primary building materials known to mankind. Over time, bricks have appeared, gained prominence, lost importance and then come to the forefront again with various styles of architecture. Burnt bricks were used in ancient Indian, Babylon, Egypt and Roman civilizations. They are still being used as filler materials for framework structures as well as to construct load bearing structures. Down the ages, there have been various interesting historic and cultural references to bricks.

- Bricks find mention in the Bible; the tower of Babel was built with burnt bricks.

- Bricks were predominantly used in the Indus valley civilisation. In fact, the civilisation was first discovered when; ancient bricks being used to build railway ballast came to the notice of a passing archaeologist.

- While the Taj Mahal was built in white marble, it had extensive scaffolding made entirely out of brick, which was pulled down after completion.

The burnt clay bricks are made by pressing into moulds, then these bricks are dried in kilns and removed.

Some bricks are made of metal-containing clay, baked at extremely high temperatures making them a ceramic material that is extremely strong and heat resistant.

When these bricks are used in walls, they require plastering or rendering and used in general work, with no special attractive appearance.

Process Of Making Bricks

The process of making a brick has not changed much over the centuries or across geographies. Traditionally the main steps followed to make a brick are explained below.

1. Material Procurement: The clay is mined and stored in the open. This makes the clay soft and removes unwanted oxides.

2. Tempering: This clay is then mixed with water to get the right consistency for moulding. Mixing is done manually with hands and feet. Sometimes and in certain areas, Tractor driven pug mills are used.

3. Molding: A lump of mix is taken, rolled in sand and slapped into the mould. Initially moulds were made of wood, now metal moulds are used. Sand is used so the brick does not stick to the mould.

4. Drying: The mould is emptied onto the drying area, where the bricks are arranged in a herring bone pattern to dry in the sun. Every two days they are turned over to facilitate uniform drying and prevent warping. After two weeks they are ready to be burnt.

5. Firing: The green bricks are arranged in a kiln and insulation is provided with a mud pack. Fire holes left to ignite the kiln are later sealed to keep the heat inside. This is maintained for a week. Firing like other operations also depends on the knowledge and experience of the brick maker.

6. Sorting: After the kiln is disassembled, the bricks are sorted according to colour and noise (by hitting 2 bricks). Colour is an indication of the level of burning.

Though the overall method remains the same, there are certain regional variations considering the local soil and climatic conditions. In different areas, different soil types are used with respect to local situation. The general approach for firing bricks include using a massive fire, a massive volume and insulation. At our Kiln we fire large volume of bricks together with pure vessel coal imported from America which makes the best quality of bricks in all the manners and the volume itself acts as an insulator to prevent escape of heat.

Properties Of Clay Bricks

Resource Management: Brick manufacturing facilities are generally located near their source of raw materials.

Sound and insulation: The characteristic thickness and density of the mud-brick wall reduces noise transmission and prevents noise from outside for a peaceful and quiet home.

Durable: Clay bricks do not warp, rust, wear, peel, or fade over time, they do not harbor termites and appear more beautiful when they are manufactured.

Low Maintenance cost: While these bricks may be expensive to acquire, their low maintenance and durability make these materials a cost-effective option for the exterior of your home.

High resale value: Clay brick homes generally have a high resale value as homebuyers prefer the upscale appearance and easy care of a brick home.

Fire resistances: These bricks do not burn and reduce the possibility of fire where they are used.

Types Of Bricks

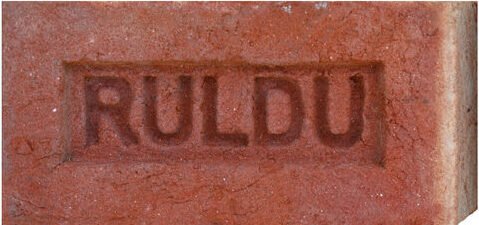

First Class Bricks :

First-class bricks are fine-looking, well-burnt in kilns, table-moulded, rectangular with sharp edges. Its surface is clean, smooth and has no cracks, these bricks are very hard bricks. First-class bricks are mostly used for face work structure or superior work.

Second Class Bricks :

Second class bricks are burnt in clamps and ground-moulds but with a slight irregularity in shape. Its surface is rough and has spots, these bricks are tough. These bricks are used in ordinary structures and places where the brick coat provided with a plaster coat.

Third Class Bricks :

The third class clay bricks are moulded to the ground and burnt in a clamp. Its surface is rough and has distorted edges, these bricks are slightly soft. These bricks are used in irrelevant and temporary structures, especially places where rainfall is not heavy.

Fourth Class Bricks

Fourth class bricks are over burnt bricks. Its surface is irregular and its colour is dark, these bricks are very hard. These bricks are used in foundations, floors, roads, etc.

Tiles :

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Crushed Bricks (Rodi)

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.